Fine Granule Surface Rubber Tile

Model No.: TD-GRF-FGS

| Tech data | Details |

|---|---|

| Materials | Recycled rubber + PU glue |

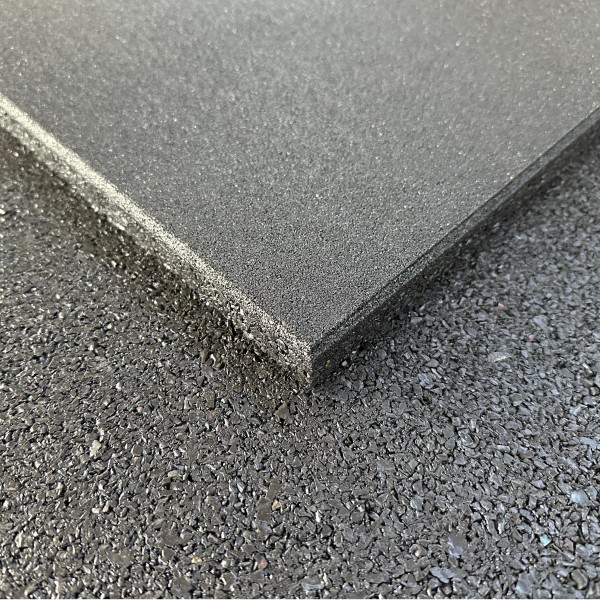

| Feature | Fine rubber granules on the top layer and coarse rubber granules as a base |

| Size | 50cm x 50cm, 100cm x 100cm |

| Thickness | 15mm/20mm/25mm/30mm/40mm/50mm |

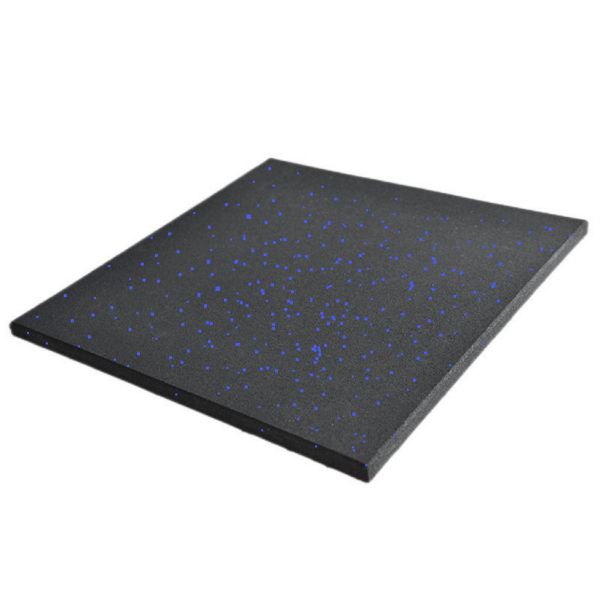

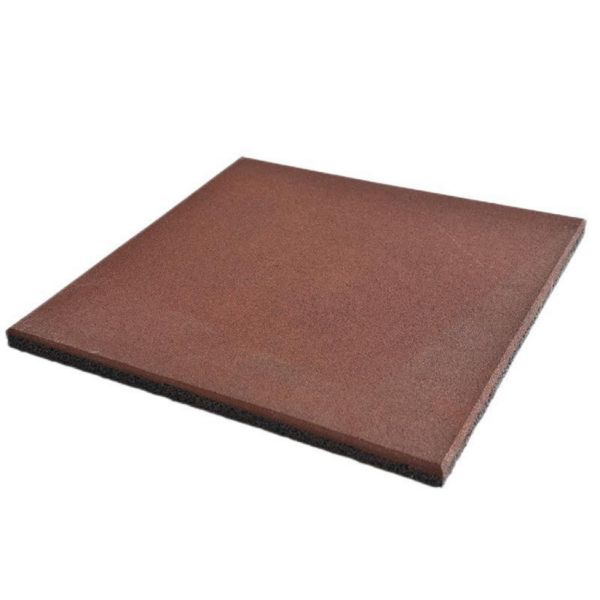

| Color | Black, Black with 15% colored flecks, Red, Green, Blue, Grey |

| Dimensional Tolerance | +/- 1% |

| Thickness Tolerance | +/- 1~2mm |

| MOQ | 300 m2 |

| Package | Pallet |

| Sample | Available |

| Custom made | Available |

Description

Our Granule Rubber Tile Series offers diverse gym flooring options to meet various needs.

Fine Granule Surface as a standard version gym rubber floor, made of fine(small) rubber granules on the top for a comfort feel, and coarse(large) rubber granules on the bottom for enhanced stability.

As the Standard Version, it has gained popularity in gyms, providing a cost-effective flooring solution without compromising on quality.

In addition to this, we offer an Pro Version - Full Fine Granule Rubber Tile to those who seek even better performance.

Black remains a bestseller, but we also provide a variety of color options such as 15% colored flecks. The regular color palette includes red, green, blue, grey, white, and yellow, and we can customize even more colors to match your specific requirements, ensuring a perfect fit for any space.

Color options

Quality Contorl

Due to the physical properties of rubber's thermal expansion and contraction, the tiles usually shrink less in the summer, so the dimensional tolerances will be slightly larger, while the tiles shrink more in the winter, so the dimensional tolerances will be slightly smaller.

In addition, the smaller the thickness of the tiles, the greater the shrinkage, and the greater the thickness of the tiles, the lesser the shrinkage.

But for the same batch, we can usually control the size difference of different tiles within 5mm.

Package

We always choose safe packaging methods to ensure that no damage occurs to the product due to packaging.

We will stack the tiles on pallets and put protective corners around them, then wrap them in plastic film, cover the top with a protective board, and finally secure them with PE/PP straps. After packing, each pallet is labeled with the item and quantity. When loading the container, we will use airbags to fill the extra space inside the container to ensure that the pallet undergoes minimal shaking during transportation, which will prevent the pallet from collapsing.